The CLARINOL® GE is mental free reactive dyes for wool, mercerized wool, cashmere and its blends. It has excellent fastness,economical and practical. It is especially suitable for dark color series and can substitute mordant dyes, can widely apply in loose wool, wool top, yarn and machine washable wool dyeing process.

• Metal free dye, ecological

• Good light fastness and wet fastness

• Brilliant color shad, complete color range

• Simple and convenient dyeing process

• Most economical dyes for loose wool and wool tops

• High fixation rate, good reproducibility, good leveling and penetrating properties

| Yellow GE | Red GE | Blue GE |

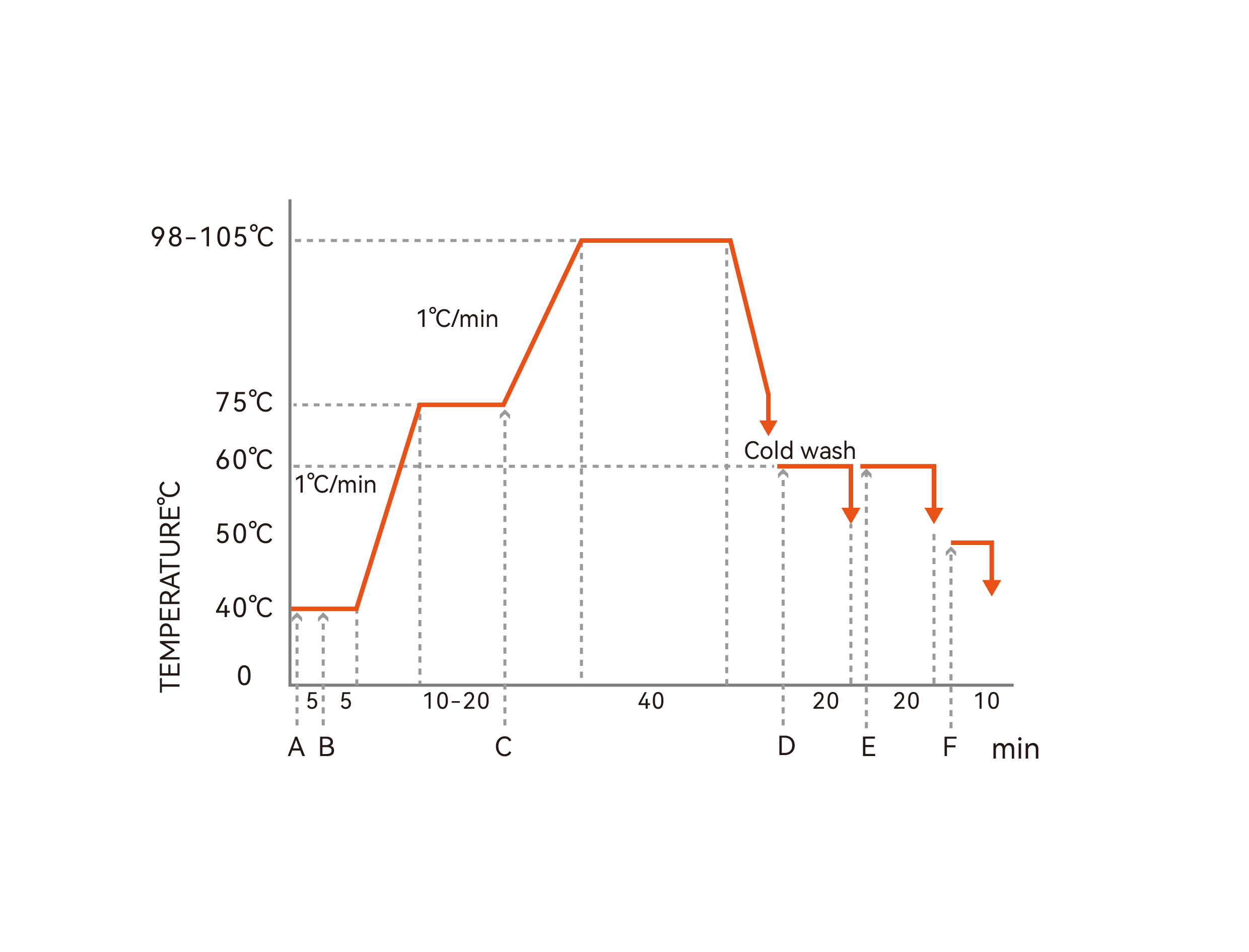

A: 1-2% Suitable Leveling Agent

0-10% Sodium Sulfate (Glauber’s salt)

4% Ammonium Sulfate

0.5-4% Acetic Acid 80% Solution pH 7-4.5

B: X% CLARINOL® GE dyes

Add Ammonia or Sodium Hydroxide (Caustic Soda) in another dyeing bath, and do the scouring at 80-85°C.

C: Y% Ammonia

Z% Sodium Hydroxide (Caustic Soda) pH 8-8.5

Warm water wash, followed by cold water wash, then acidified to pH 5.0 by Acetic Acid.

A: 0.3-0.8% Suitable Leveling Agent

0-10% Sodium Sulfate (Glauber’s salt)

4% Ammonium Sulfate

0.5-4% Acetic Acid 80% Solution pH 4-4.5

B: X% CLARINOL® Black GE dyes

Warm water wash, then repeat 5 times of Alkali water treatment at 60°C with 1g/liter of Sodium Hydroxide (Caustic Soda) solution. Same as the above "C" section.

Remark: the dyeing depth for black is 1%、4%

All information is only for reference, customer must confirm by testing for it's intended conditions of use. It should not be construed as guarantee specific properties of the products described or their suitability for a particular application.