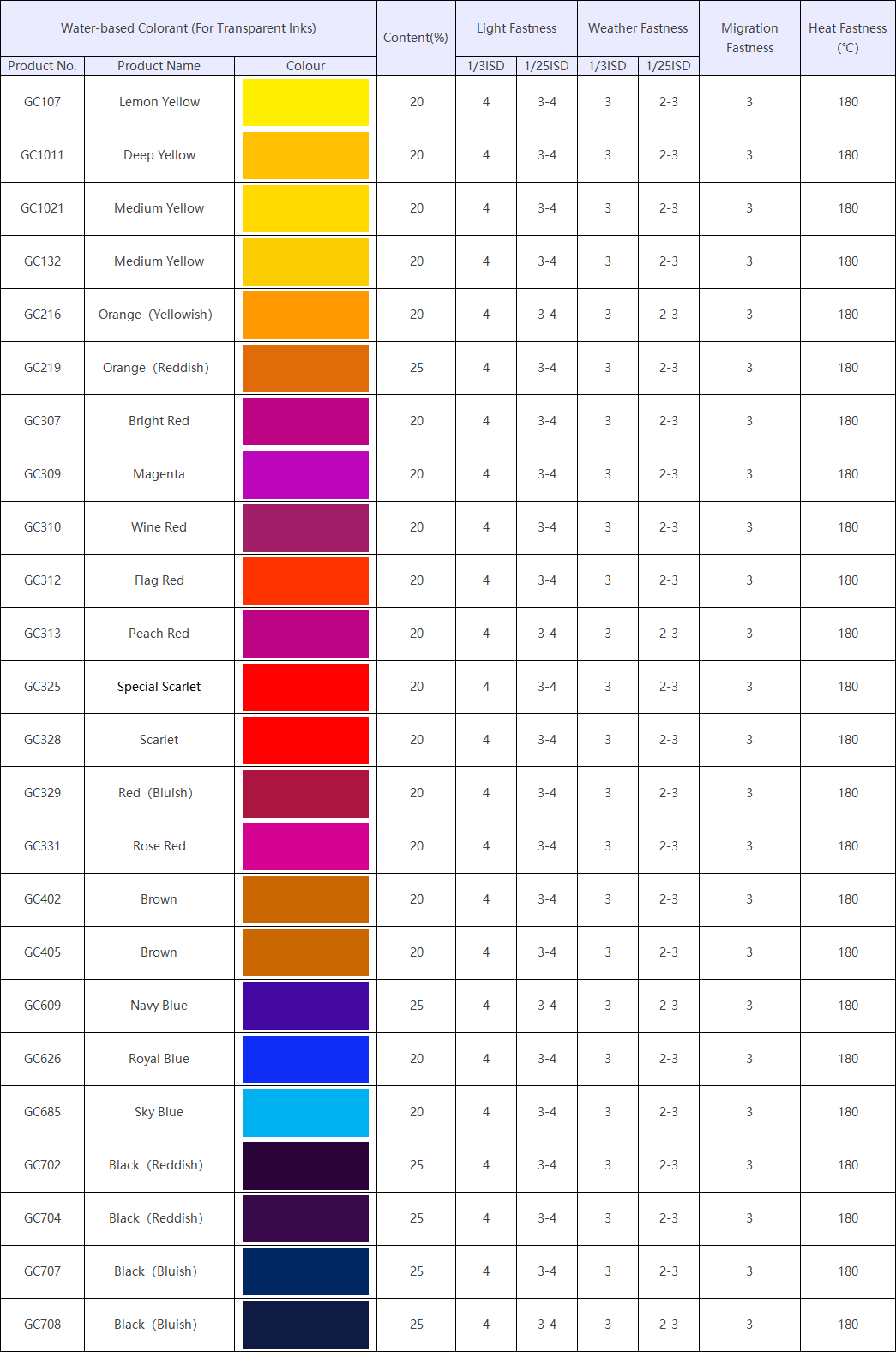

This high-performance colorant is specifically developed for the water-based coatings industry. By graft-modifying traditional colorants, it demonstrates excellent solubility in water, ethanol, ethylene glycol, and ethylene glycol ethers. It has outstanding compatibility and stability with water-soluble varnishes or alkali-soluble resins, effectively addressing the compatibility issues associated with traditional colorants. This series of colorants offers high strength, excellent fastness, and vibrant colors, making it a more environmentally friendly, high-tech product.

Applications

• Coloring of water-based aluminum foil varnishes

• Coloring of water-based hot stamping foil coatings

• Coloring of water-based wood coatings

• Coloring of water-based leather spray coatings

• Coloring of water-based baking paints for metal, glass, and ceramics

Usage Instructions

1.Dissolve the dye in deionized water and ethanol, ethylene glycol, or ethylene glycol ether solvents (water 40%, dye 20%)

2.Stir until fully dissolved, then filter for use (color concentration should be around 20%)

3.Add the filtered dye solution into the water-based resin

4.Stir evenly (high-speed stirring for 3-5 minutes)

5.Apply to the machine for coating or spraying

This colorant is specifically developed for the water-based baking paint industry, utilizing graft modification technology. It features high color strength, vivid colors, and excellent transparency. In addition to being environmentally friendly, it offers outstanding heat resistance, with only slight color changes after baking at 180°C for 30 minutes. It is compatible with both solvent-based and water-based coatings, making it widely suitable for high-temperature baking paints.

Applications

• Water-based metal, ceramic, and glass coatings, plastic coatings

• Water-based decal printing

• Water-based hot stamping foil coatings

Features

• Lightfastness reaches 6-7 grade (except for Peach Red and Royal Blue), maintaining color stability without migration or fading after baking at 180°C-200°C for 30 minutes

• Good compatibility with both solvent-based and water-based coatings, with wide applicability

• Bright colors, high concentration, and stable performance when diluted with water

• Fast drying with excellent wet rub resistance, ideal for water-based or alcohol-soluble baking paint spraying processes

• Free from emulsifiers, surfactants, and prohibited solvents like DMF (dimethylformamide), with heavy metal content compliant with environmental standards

• Color tone and concentration can be flexibly adjusted according to customer requirements

Usage Instructions

1.Add the dye solution into the water-based resin (avoid reverse addition), with the addition amount not exceeding 30%

2.Stir evenly (high-speed stirring for 3-5 minutes)

3.Apply by machine coating or spraying

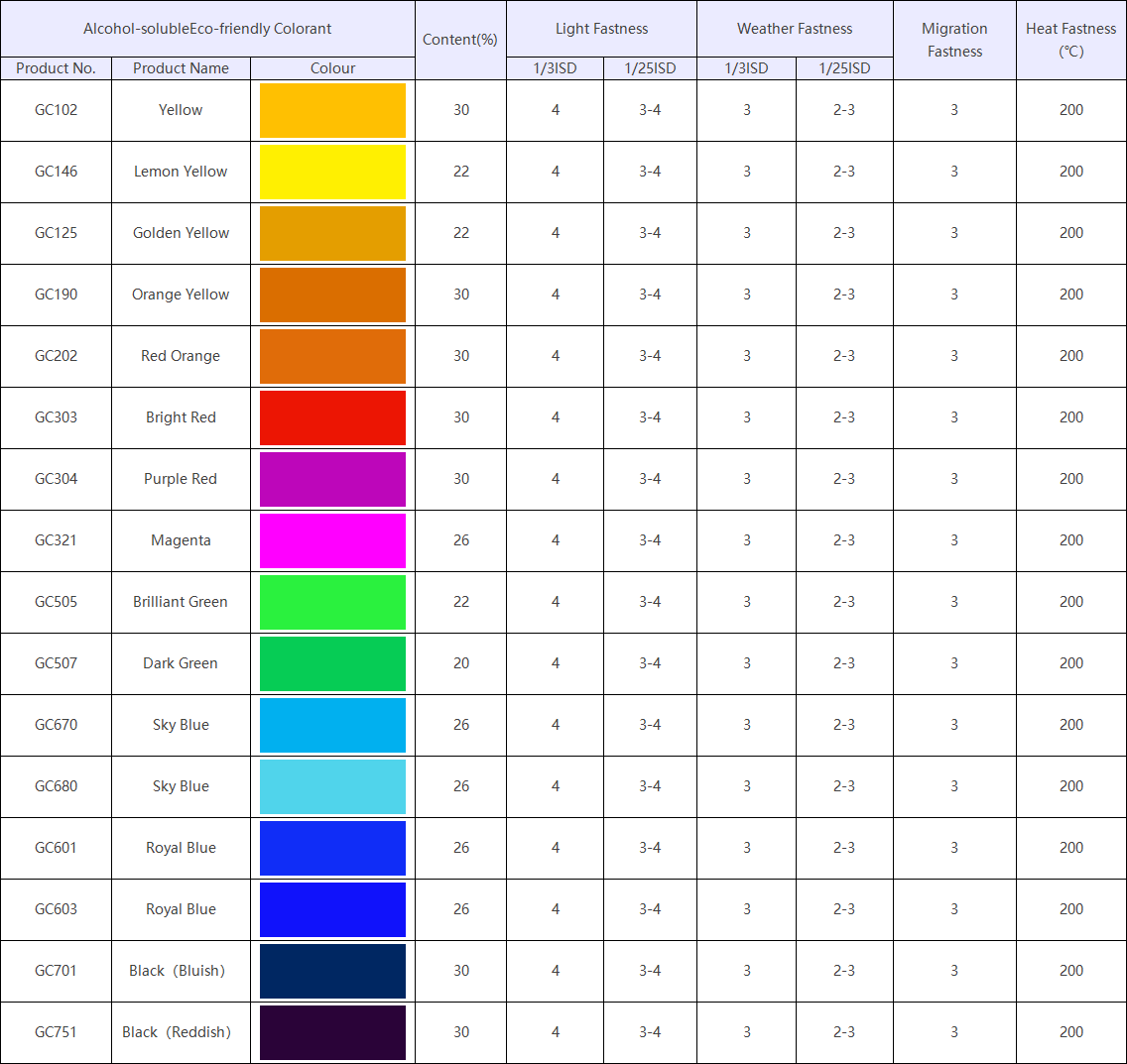

This high-performance colorant is specifically developed for the cigarette packaging industry, utilizing graft modification technology. It demonstrates excellent solubility in ethanol and is highly compatible and stable with alcohol-soluble varnishes or alkali-soluble resins, effectively addressing the VOC issues associated with traditional colorants. The product features vibrant colors, high strength, and excellent fastness, withstanding high temperatures and maintaining color stability after baking at 180°C for 30 minutes. It is suitable for high-temperature baking paints and various solvent-based coatings, making it an eco-friendly, high-tech dye.

Applications

• Coloring of alcohol-soluble transfer coatings

• Coloring of alcohol-soluble aluminum foil varnishes

• Coloring of alcohol-soluble hot stamping foil coatings

• Coloring of cigarette tipping paper ink

Features

• Good compatibility with various solvent-based coatings

• Bright colors, high stability, and concentration, with superior heat resistance

• Suitable for oil-based baking paint spraying, with fast drying speed

• Color tone and concentration can be flexibly adjusted according to customer requirements

Usage Instructions

1.Dissolve the dye in ethanol, with a ratio of 20% dye and 80% ethanol

2.Stir until fully dissolved, then filter for use (color concentration approximately 20%)

3.Add the filtered dye solution to the alcohol-soluble resin

4.Stir evenly (high-speed stirring for 3-5 minutes)

5.Apply by machine coating or spraying

All information is only for reference, customer must confirm by testing for it's intended conditions of use. It should not be construed as guarantee specific properties of the products described or their suitability for a particular application.