CLARIA® GP is a type of acid dye with reactive groups, which is metal-free (with the exception of CLARIA® Navy GP-G and CLARIA® Black GP-R series). It has been specifically developed for nylon dyeing applications.

The CLARIA® GP series dye is especially developed for bright shades, applied to nylon/elastane blended fabrics, offering extremely high wet fastness. It overcomes the limitations of traditional dyes in terms of dye-uptake and fastness.

This series also provides exceptionally high light fastness for bright shades and can achieve high light fastness ratings.

The dyes in this range exhibit excellent compatibility, meeting the highest requirements for all nylon textiles, and are particularly noteworthy in bright shades as well as black and navy colors.

Dissolving CLARIA® GP Dyes

In modern dyeing machines, CLARIA® GP dyes are dissolved in a specific amount of hot water (60 to 80°C), using a high-speed stirrer, forming a stable solution according to each dye's solubility properties.

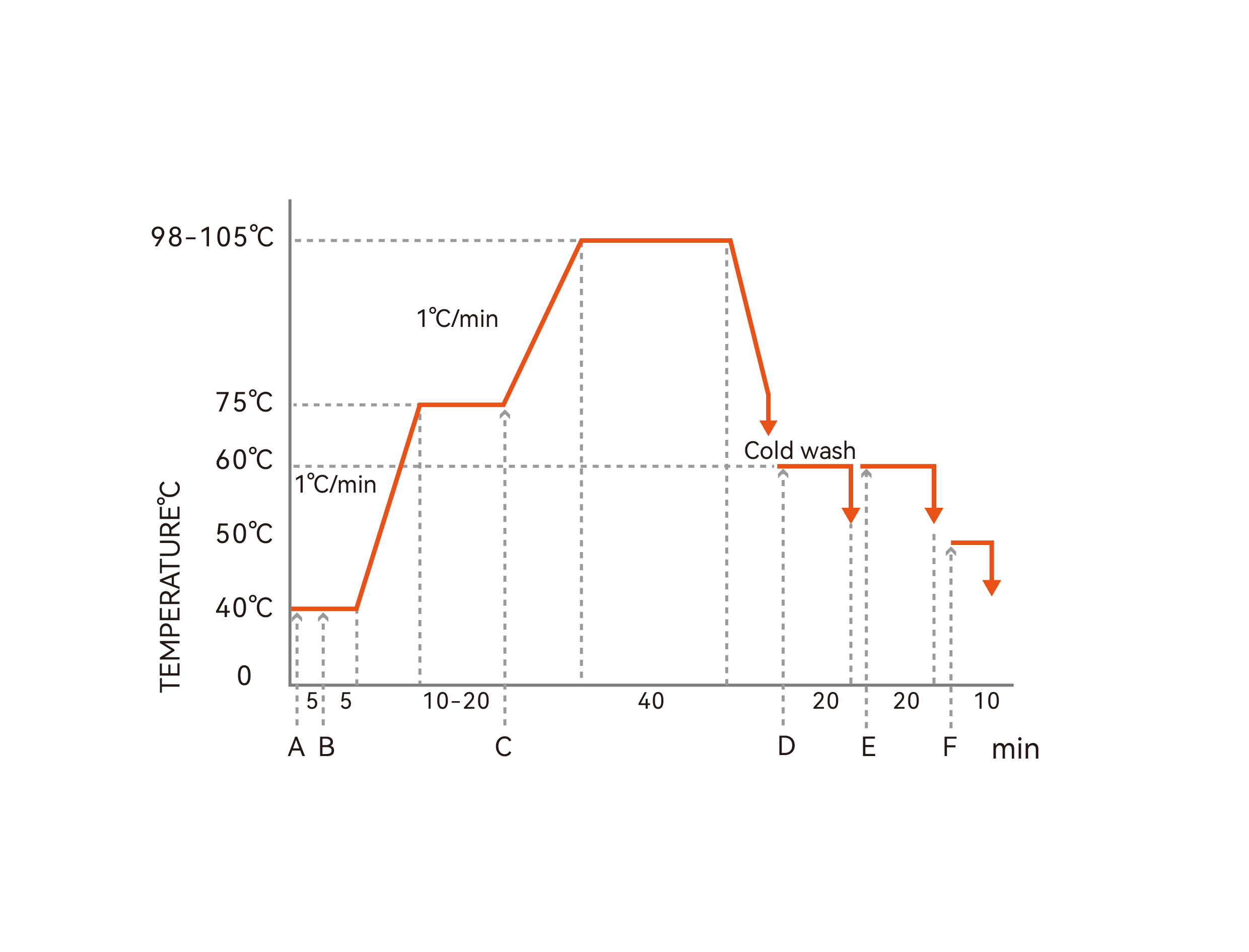

CLARIA® GP Superfine Fiber Dyeing Process

| A: | 0.5 | g/l | Penetration Enhancer |

| 2.0 | g/l | Acid Buffer | |

| 1.0 | g/l | Lubricant | |

| pH 5.5 | |||

| B: | x | % | CLARIA® GP Dyes |

| C: | 10 | % | CaCl2 |

| D: | 0.5-1 | g/l | 36° Bé Sodium Hydroxide |

| y | % | CLARIA® GP FIX | |

| pH 11.0(final PH) | |||

| E: | 1.0 | g/l | Sodium Carbonate |

| 2.0 | g/l | Soap Detergent | |

| F: | 0.5 | g/l | Acetic Acid |

| pH 5-6 | |||

| A: | 0.5 | g/l | Penetration Enhancer |

| 0.5-1 | g/l | Leveling Agent | |

| 2.0 | g/l | Acid Buffer | |

| 1.0 | g/l | Lubricant | |

| pH 5.5 | |||

| B: | x | % | CLARIA® GP Dyes |

| C: | 2 | % | CaCl2 |

| D: | 0.5-1 | g/l | 36° Bé Sodium Hydroxide |

| y | % | CLARIA® GP FIX | |

| pH 11.0(final PH) | |||

| E: | 1.0 | g/l | Sodium Carbonate |

| 2.0 | g/l | Soap Detergent | |

| F: | 0.5 | g/l | Acetic Acid |

| pH 5-6 | |||

CLARIA® Black GP-R and Calcium Chloride

Due to its larger molecular structure, CLARIA® Black GP-R has a higher affinity for fibers compared to other CLARIA® GP dyes, allowing for better absorption. Therefore, 2% calcium chloride is sufficient to achieve optimal fiber dyeing. Excessive calcium chloride may lead to dye precipitation and spotting. If machine conditions allow, calcium chloride can be added at the boiling point. This helps avoid dye accumulation in the foam on the solution's surface, which could cause dye spots.

Dyeing Temperature for CLARIA® Black GP-R

To ensure adequate color depth and dye-uptake, raising the dyeing temperature to 105℃-110℃ is the best way to deepen black shades. Laboratory machines must also reach this elevated temperature.

Compatibility of CLARIA® Black GP-R

CLARIA® Black GP-R can be combined with CLARIA® Navy GP-G to serve as the base for deep blue and dark blue shades. The minimum usage of CLARIA® Black GP-R should not be less than 1%. It is not recommended to use CLARIA® Black GP-R as a primary color element in combined shades.

Remark: the dyeing depth for black is 1%、4%

All information is only for reference, customer must confirm by testing for it's intended conditions of use. It should not be construed as guarantee specific properties of the products described or their suitability for a particular application.